Application

Racing

Racing

We are the leaders in inverter testing. So that you will lead in the future.

Motorsport is a forum for innovation in electro-mobility. We have been at home in Formula 1 for years.

Hybrid systems have existed on racing circuits all over the world for a long time that work bidirectionally and also directly mechanically connected to the powertrain (KERS) or support the combustion engine via an electrically powered turbocharger (HEAT), whereby energy is also recuperated via the intake function of the turbocharger.

Electric drives as a core powertrain system have arrived in racing in Formula E.

Power electronics play an important role in all motorsport applications that use one or more electric motors. The optimal control of the e-motor and the control of the energy flow between the systems (where there are more than one motor) and the battery represent important differentiating features.

The electrical rotating field frequencies that the inverter must produce for the turbocharger (HEAT) lie between four and five kilohertz. KERS lies not far away.

Do you still want to cross the line with it?

To test the inverter, many test layouts use real e-motors which, however, are associated with particular challenges:

High costs for the high-performance motor

Wear on high-performance motors

Difficult compensation of inertia in the load system

Use of reduction gearboxes to adapt the high speeds to the dynamometer

Limits in the dynamics of mechanical load systems

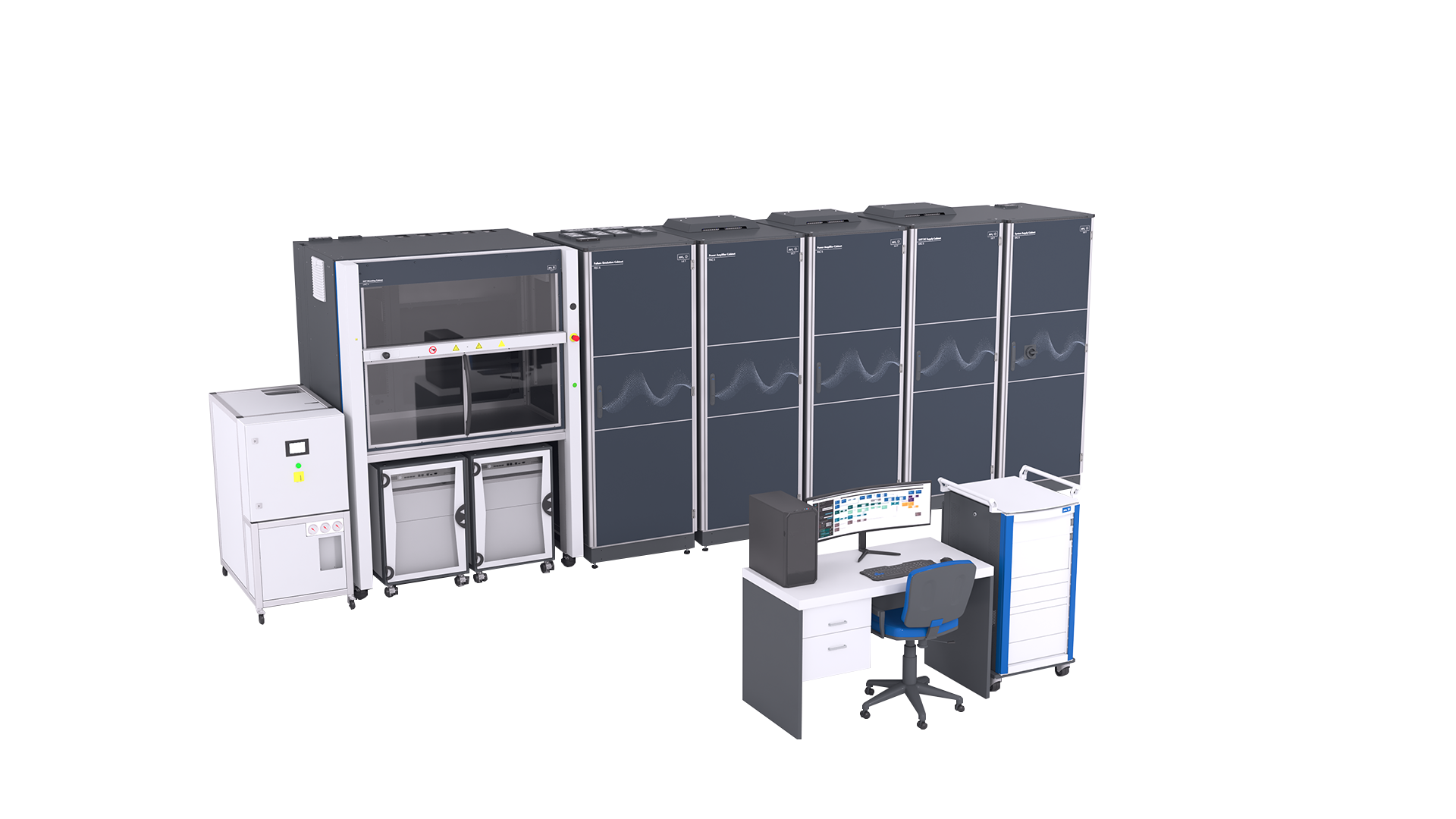

The big advantage of AVL SET test solutions!

The FIA regulations in Formula 1 define time limits for the testing of components (e-motor, battery, inverter). This is where the use of e-motor emulators that reproduce the characteristics of an e-motor can deliver significant advantages. The high speeds that dynamometers cannot reproduce without reduction gearboxes can be easily reproduced by emulators. This eliminates all the unfavourable influences of a reduction gearbox and the limiting characteristics of dynamometers. Eliminating real e-motors can save money and reduce the effects of wear to zero.

Highlight: A particular advantage in view of the FIA regulations: If no real e-motor is used for the test, there is no limit to the testing time!