The future is electric

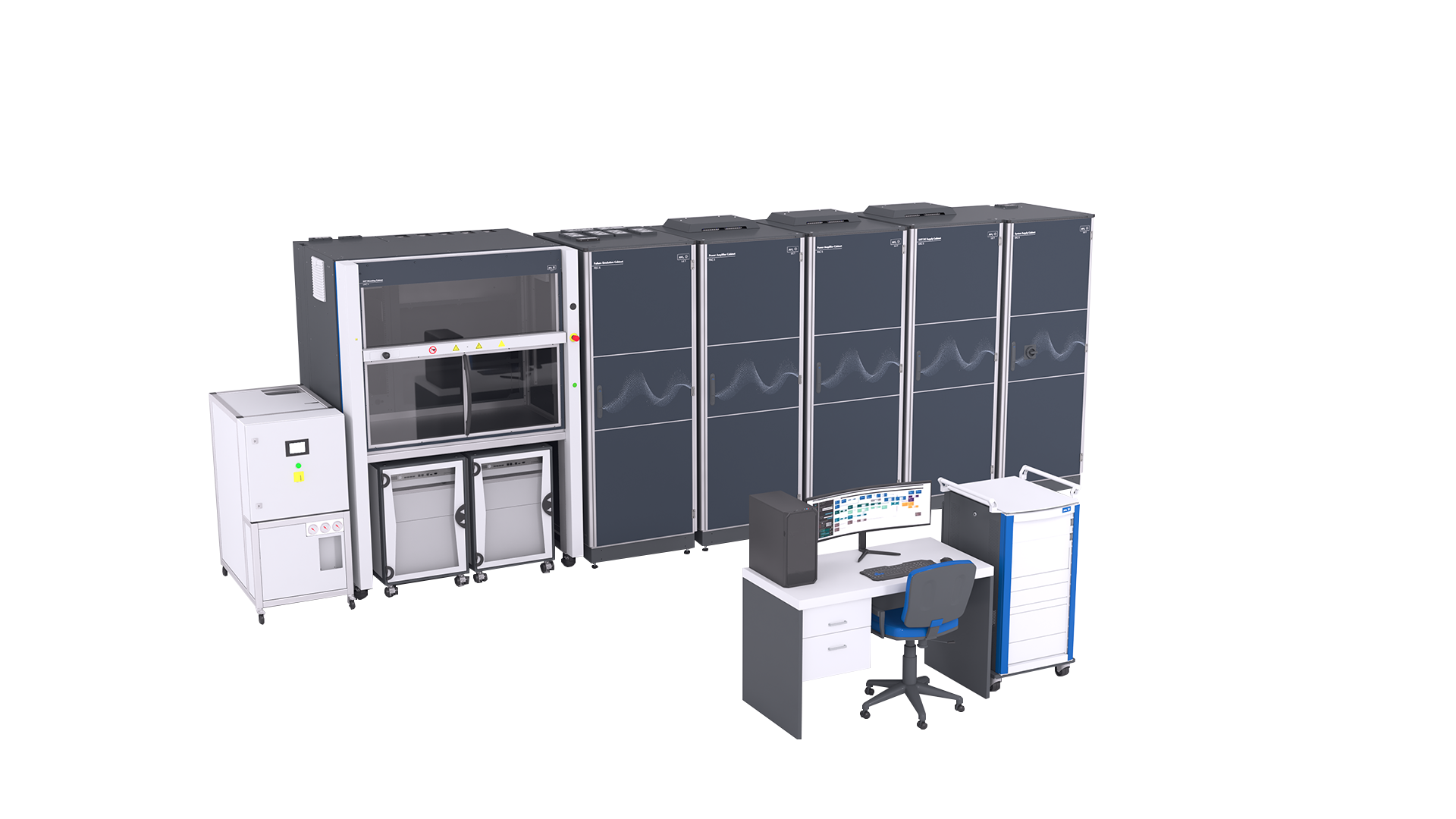

AVL Inverter TS™

The AVL Inverter TS enables the validation of the inverter already in an early development phase and optimizes the integration with all other components in the electrified powertrain.

Keyfacts

Product phase

Development

Validation

UUT

Inverter

DC/DC Converter

Modularity

1 UUT with 2x 3ph e-motor

2 UUT with 2x 3ph e-motor

Motor models

PMSM

IM

EESM

Your Challenge

Our Solution

The AVL Inverter TS enables the validation of the inverter already in an early development phase and optimizes the integration with all other components in the electrified powertrain. We have designed a test environment, where all functionalities and failure modes can be optimized, tested and pre-calibrated efficiently. Compared to testing in prototype vehicles, this not only results in optimized processes but significant time savings.

Highlights

- Worldwide reliable and reproducible test results

- Fully comprehensive, accompanying test methodology development

-

Flexible, accurate and fast mapping of all common motor concepts

-

Emulating fault situations and testing the inverter behavior

-

Low connected loads, large active power

-

Future-proof through the coverage of high voltage levels

-

Smallest footprint thanks to customer-oriented configuration

- Use of the original software and parameters in the inverter